- Our system has been used successfully for many years in a related field to pinpoint leaks in liquid pipelines.

- We provide a technician trained to use the leak locating system, a line locator to identify the pipeline and any other equipment required to perform the service accurately.

The initial response

- A gathering system layout is required.

- We then determine if there are any breaches in a gathering system through the use of a process that is non-intrusive and does not interrupt the daily operation of the system.

The follow up

- Based on the information gathered from the initial survey, we then either proceed to the next gathering system or identify the exact location of the breaches to the pipeline system.

- A report is produced with the locations of breaches identified on a gathering system map.

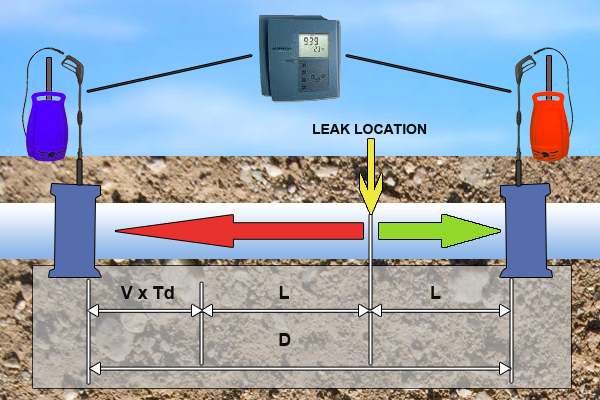

- In the “Classic” Correlation process, two sensors are placed at intervals on a direct connection to the pipeline (valve or pig sender/receiver location).

- Noise is created by the leak as it escapes from the pipeline under pressure.

- This noise is conducted in both directions away from the leak through the wall of the pipeline.

- These are small vibrations and in the liquid as a pressure wave. The leak noise travels at a

- constant velocity towards the nearest sensor and arrives there first. The arrival time at each sensor is registered and the difference between the two arrival times combined with the knowledge of the type of wall material and the length between the sensors enables the microcomputer to calculate the location of the leak.

- This accuracy can be to within centimeters.

- Leak Locating: Classic Correlation

- The principle of correlation:

- L = '12 (D-(VxTd)).

Typical Configuration: