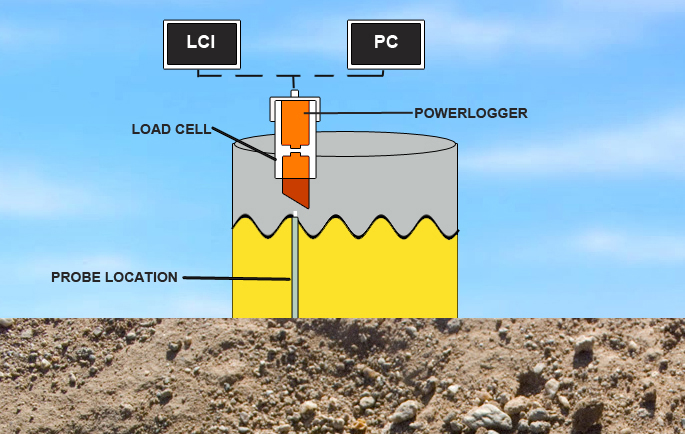

Buoyancy Force changes are monitored by the load cell and stored in the Data Logger.

Buoyancy Force Measurement is constant with Mass Quantity. Constant Mass is maintained when the buoyancy force applied to the suspended probe is constant. Therefore, constant mass indicates a tight vessel.

Mass increases reflect a decrease in buoyancy force on the suspended probe and indicate a vessel leak or valve failure.

Vessel Integrity Verification is determined through the constant monitoring of the buoyancy force data. The computer analysis of the accumulated data identifies changes in mass quantity and with integrity verification determined by the rate of change.

The mass-based leak test procedure, with modifications, is an accurate cost effective means for testing the integrity of your AST.

This procedure can be used to test all oil field liquids. Results can be achieved in approximately 2 hours depending on the size of the vessel and type of product. These factors do not affect the test procedure, but may affect the test period.

The leak test system has been independently certified to detect a leak of 0.1 gallons per hour.

This testing system is fully certified to 25 feet of liquid level.

- The technician will identify himself to the Contact person at the site and obtain a safe-work permit.

- A Tail-Gate meeting will be held with all concerned parties to explain the test procedure and gain specific site information.

- The Vessel must have a minimum of 1.8 meters liquid level.

- The vessel to be tested will be identified and appropriate safety measures will be taken, such as H2S, LEL and O2 Levels.

- Confirmation that the vessel is shut in from operating systems will be made.

- The Technician will perform a walk around the vessel to check for any visible leaks from the man way and associated piping. Information will then be gathered from the Identification Plate.

- The Technician will access the top of the tank to take measurements and gauge the amount of liquid.

- The Technician will monitor the test data periodically during the test. The test will take a minimum of One Hour to collect data.

- At the conclusion of the test, the Technician will remove all of the test equipment and return the safe work permit to the originator or their designate.

- The vessel may then be returned to normal service or remedial action taken.

Typical Above Ground Storage Tank:

:

: