Retail Precision Tank Leak Test Procedure:

This UST testing procedure provides you with vessel integrity verification with minimal disruption to your operation.

Test results can be provided in approximately 2 hours depending on the size of the vessel and the type of product.

This testing method is the fastest, volumetric precision leak test to be certified by the U.S. E.P.A.

We use the ALERT 8200 mass-based precision leak test procedure.

- The technician will identify himself to the contact person at the site and complete the safe work documentation.

- A Tail-Gate meeting will be held with all concerned parties to explain the test procedure and gain specific site information.

Step 1: Acoustic Pressure Ullage Test:

- Isolate the Vessel.

- Place acoustic sonde into the riser with proper sized plug and silicon to ensure proper seal.

- Plug other associated piping with proper plugs to isolate system.

- The Technician will then perform a reference test for background noise.

- If the test comes back 'High', the Technician will check all valves to the tank to ensure a valve or plug is not leaking.

- If after these steps are taken and the reference remains high, piping unions will be exposed to plug and isolate the unions.

- After the reference test is acceptable, the next step will commence.

- Technician will then deliver nitrogen into the vessel, pressuring it to the required test pressure.

- Technician will then check plugs for leaks using soapy water. If no leaks are detected and the test is valid, the pressure test will begin (this is performed by the proprietary software).

- The Technician will monitor the test until completion, at which time a PASS or FAIL will result.

- The test equipment is removed and the next step for the precision tank leak test will begin.

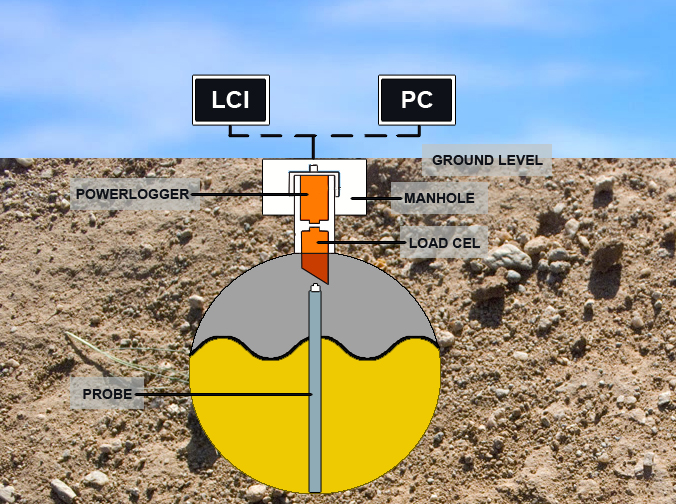

Step 2: Bouyancy Displacement Leak Test Procedure:

- The proper sized probe will be placed into the tank attached to a load cell.

- The load cell will be attached to a data logger.

- The precision tank test will be monitored by the technician.

- When the tank has passed the precision tank leak test the test equipment will be removed and the tank placed back into service.

- If the tank does not pass the precision leak test the technician will remove the first set of test equipment and replace it with another set of test equipment and re-run the test.

- Should the second test show the same failure the tank will be isolated and the operator advised of the results.

- All appropriate paperwork will be signed and the technician will leave the site.

Typical Under Ground Storage Tank: